| ||

| CAREER | Home | My Site Map |

|

BOEING - SUMMER 1989 During the summer of 1989 I received an invitation to participate in the internship program at Boeing Airplane Company in Seattle, Washington. I spent three months living and working in Kent, Washington at the turbine engine and strut department. The strut (or Nacelle's) is the portion of the plane that attaches the turbine engine to the wing. During my internship I did material crack tip growth from rotational vibrations. These calculations were used to determine the necessary width of material required to cover the Nacelle's. Unfortunately at the time our computer resources and techniques were extremely primitive. Now I'm sure they can accomplish much more than we were ever able too. The internship was great because in addition to my work all of the interns met once a week and did future growth projects. One of the major projects we tackled was for the Boeing 777 plane which is now in production. We worked on all kinds of problems from design through production. I think was Boeing's way to pick out their future engineering stars. Another part of the intern program was to do tours. We toured both the Boeing 747 and 767 plant in Everett, Washington and the 737 and 757 plant in Redmond, Washington. Interns were allowed into the testing facilities, wind tunnels, even some of the military development testing facilities. Boeing and Washington were a great experience for me but I definately felt lost there. At that time there was something close to 50,000 people working directly for Boeing in the Everett through Kent area. I definately decided at that time that this was not the place for me. I felt lost in such a huge crowd. |

|

WESTINGHOUSE at the Idaho National Engineering Laboratory - FEB 1991 During my senior year in college (late 1989, early 1990) the recession was just beginning to hit the economy and all the promising positions (including Boeing) dried up. Everyone was in a panic. We had all gone to school in the engineering profession because we felt it would provide us with an excellent opportunity for steady employment. But these were the jobs hit the hardest during the recession. I was one of the most fortunate people in my graduating class. I had two job offers. One was for a position with Westinghouse at their nuclear submarine development laboratories in Idaho Falls, Idaho. I was thrilled with this opportunity. We got to go to Florida for six months and go through the same training they put Naval nuclear submarine officers through. Then upon out return to Pocatello we would begin one year's worth of training on the Naval nuclear submarine simulation programs. Finally, once we had all passed those test we would begin working on the design and development for the Navy's nuclear submarine program. I thought this would be a great opportunity, plus I would be only one state away from home and back near my Rocky Mountains! However, there was a problem. You had to have a security clearance and that could take nearly a year. So, I filled out the paperwork and waited. In the mean time a local Anchorage company ARCO came knocking at my door. After a one day grueling interview they gave me a job offer which was EXTREMELY handsome to someone who had been very poor for the last four years. So, while I waited to hear from Westinghouse. But then, I waited, and waited, and finally I had to begin working at ARCO. Nearly one year to the day I submitted my paperwork for the security clearance I recieved it and they called me to take the position. Stupid me I got mad and rejected them. |

|

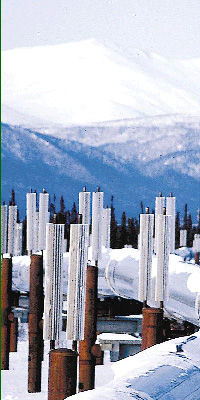

ATLANTIC RICHFIELD COMPANY (ARCO) now BRITISH PETROLEUM (BP) - SEPT 90 - OCT 91 I began my first year of working at ARCO in the Process Engineering group. This group dealt with all of the natural gas processes throughout the oil extraction in the fields. They had an Engineering Development Progam (EDP) for al fresh-outs. During this program you went through each of the different departments and worked on a problem to develop your skills. I started out in the Process division where I went to the North Slope frequently to learn about the different parts of the plant and how they all worked together. Next I went to the Drilling group where I again went to the slope often to see the actual exploration and drilling. My next assignment was in the Corrosion group. This was the funnest assignment. I developed a test to measure the level of surfactant necessary to inject into different pressured lines of fluid. I built the test apparatus and conducted all the testing myself and wrote up the final recommendations. At that point I felt most like an engineer. I finally ended up in the Reservoir group where I investigated the affects of natural gas injection rates and quantities on the different pumping stations in the field. There were two major events that happened while I was working at ARCO worth mentioning. There were major storms on the North Slope which are catagorized into phases. A phase 1 storm is pretty nasty but a phase 3 storm requires lockdown of all individuals at their exact location. Well, I had gone up during January and I had heard there was going to be a phase 3 storm coming up that evening and I wanted to get home. The only plane leaving was out of the BP camp which was many miles from the ARCO camp. This was the one and only time I got a major dose of the "Alaska" experience. We started out in a small twin engine plane which hopped us to a drilling station (in ice fog no less). From the drilling station we had to take a school bus to a processing plant. During this portion of the trip we nearly got stranded in a huge snowdrift because the driver couldn't see very clearly. At the processing plant we still needed to get to the main camp so we could get to the airfield and on the 757 flying back to Anchorage. The storm was moving upon us fast so we jumped into a deisel truck (they are always left running up there in the winter or the engine block may freeze) and four of us crowded into the cab drove the last few miles to camp. We just barely made the plane which was the last one to take off for a week because of the severity of the storm. The next story again involved being stuck at the water treatment plant out on a spit of land jutting into the Bering Sea. This plant was iced in during the winter, miles from the nearest processing plant, and it seemed light years from the base camp. So, when a storm came up (as they did frequently near the water) there was little to no travel let alone communications with the other people. The guys there loved to take the newbies and tell them nightmare stories about being stranded out there. Well, one time they were telling me a story about polar bears that congregate around the plant because seals occasionally got suck into the water inlet lines, subsequently died, and the smell attracted the bears. Now I'd been there long enough to not believe everything I was being told. But, next thing I knew they were inviting me out onto one of the platforms off the station which are very slick things because of the ice) and there below me was a polar bear (very young) eating one of the seals that had floated up out of the holding tank! COOL! There were three more cool things about working for ARCO. First, I got to spend nearly a month in Dallas, TX (in July unfortunately) during the EDP training program. Second, we constantly developed our programs in UNIX and the company had a fleet of Cray computers in Seattle Washington that we ran all our simulations through. So, the technology was great. Finally, the company owned all the planes that flew back and forth to the North Slope. So when the planes needed to be serviced they would shuttle people back and forth to Seattle. Each person got at least one reserved trip (with family) per year and then could be on standby whenever. But the bad part. Well, first I was laid off nearly one year to the date I was hired during the economic downturn following the end of the Gulf War. The company laid off nearly 12,000 people internationally. I was crushed. But I didn't let that deter me. I got a great package (6 months pay, health insurance, moving expenses back to Colorado and payment of my school bill for the year). And I moved home to Colorado!!!!! |

Schriever AFB |

GTE - JAN 92 - JUN 92 I worked for GTE on a small contract to do maintenance on the communications installations at Falcon Air Force Base (now Schriever AFB). One of the women I worked for had a sister who just got hired on a new contract called DSC. She took my resume in and that was when I got my next job. |

| No image | BENDIX FIELD ENGINEERING (BFE), ALLIEDSIGNAL TECHNICAL SERVICES (ATSC)

HONEYWELL TECHNICAL SERVICES INC (HTSI) These are the progressions of the name of the company I have worked for since 1992. I originally began work on the Depot Support Contract (DSC) I and progressed to II. In 2001 the company successfully rebid the new contract which is called the Air Force Satellite Control Network Contract (SCNC) If you'd like more information on my current position please contact me:

|

| Top | My Self | My Family | My House | My Genealogy | My Travels | My Scrapbooks | My Job | ||

|

www.pcisys.net/~derrica v.2001-2003 | ||